Intelligent gasket

![]()

Bolted connection has the characteristics of easy installation and disassembly and reusable, which is widely used. However, in various extreme conditions such as vibration, impact, load variation, temperature difference and so on, the bolt connection will often loosen and lead to structural failure. So it is very important to monitor bolts of key joints in real time.

Our company has invented an intelligent gasket technology with anti-loosening function to monitor the fastening state of bolts. Compared with other intelligent fasteners based on grating type, piezoelectric sensing type or resistance strain gauge type, this product has low cost, high reliability, and can effectively monitor the bolt fastening state while having certain anti-loosening function.

Design principle

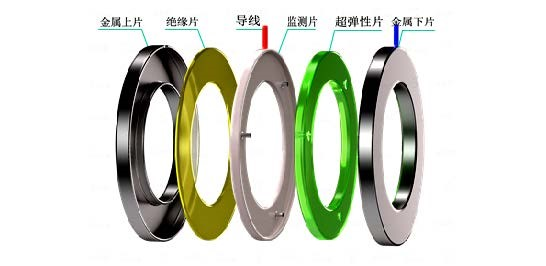

Intelligent gasket by monitoring the state change of the internal circuit to characterize the bolt connection state, mainly composed of metal upper piece, insulation piece, monitoring piece, super elastic piece and metal lower piece. Among them, the metal upper and lower pieces not only bear anti-scratch, but also play a sealing protection role. Both the insulating sheet and the superelastic sheet are made of insulating material, so that the monitoring circuit is not conductive to the metal upper and lower pieces (the thickness of the gasket in this case is 3mm, which can be applied to M16 and M20 bolts according to GB/T3103.3-2000). Its working principle is to realize the signal state change of the internal circuit by adjusting the structure and material parameters of the internal monitoring plate and the hyperelastic plate according to the requirements of different tightening torques, so as to characterize the connection state of the bolt. The technology can provide a series of specifications based on tightening torques to meet the requirements for monitoring the connection status of bolts of different types (corresponding to different tightening torques).

Technical advantages

Compact structure, high reliability: by monitoring the internal monitoring circuit state changes, feedback bolt connection.

High sensitivity: the change of bolt stress state is relatively direct, and the monitoring accuracy of tightening torque change can reach 5%.

Strong environmental adaptability: the materials and devices used can meet the application environment of -55℃-70℃, overload peak 100g.

The monitoring module is small in size, light in weight and low in energy consumption. The system adopts low energy consumption design (< 0.2W) and wide power supply range (USB interface 5V power supply or DC 5V ~ 48V power supply).

Low cost, strong versatility, with anti-loose function:

Compared with intelligent fasteners based on grating type, piezoelectric sensor type or resistance strain gauge type, the cost is low, easy to replace and maintain, while effectively monitoring bolt fastening state, but also has a certain anti-loosening function.

Monitoring programme

n actual use, according to the requirements of different tightening torques of bolts, the corresponding intelligent washers with different tap positions can be selected to judge whether the bolts are loose by internal monitoring circuit on-off signal: when the bolts are at the specified tightening torques, the circuit is in the path state; When the bolt is loose (i.e., when the tightening torque is less than the specified value, the change monitoring accuracy can reach 5%), the circuit is in the open state, and the channel status indicator (LED) changes from green to red. The on-off state of the circuit is transmitted to the terminal signal receiving and processing module, and the inspection period can be set according to needs. Single point wired/wireless monitoring can be adopted for heavy parts connected by a single bolt. The single point wireless monitoring scheme for bolt loosening based on intelligent washers is shown in Figure 2. For adopting many of bolt connection structure, can be connected by short cable network mode first, and then adopt the way of wired or wireless signals in the monitoring module, which is based on intelligent washer is loose more short cable network monitoring scheme is shown in figure 1, and can through the way of "copy meter" to judge the fault bolt, as shown in figure 2.

|

FIG. 1 Single point wireless monitoring scheme of bolt looseness based on intelligent washer |

FIG. 2 Monitoring scheme of bolt loosening multi-point short-distance wired network based on intelligent washer |